746 1-800-452-1261

FLINN METHOD

#11 Silver Compounds

Silver and silver compounds are expensive and may be recovered or recycled

but often can be reclaimed for future use. Silver compounds are characteristic

hazardous wastes. Silver compounds are identified by the EPA as characteristic

hazardous wastes due to their toxicity. According to the Resource Conservation and

Recovery Act (RCRA), the concentration of silver ions in an extract of a solid suitable

for landfill disposal cannot exceed 5 mg/L, based on the Toxicity Characteristic

Leaching Procedure (TCLP). Federal guidelines also impose a concentration limit

of 5 mg/L on industrial sewer disposal of silver ions in solution. Check with your

local sewer authority for the allowable discharge limit in your area. In most cases,

dilution with water is not an acceptable means of achieving the concentration limit.

Examples

Silver nitrate, silver chloride, silver oxide

Materials Required

Nitric acid, HNO3, 8 M

Sodium chloride, NaCl, 1 M

Sodium hydroxide, NaOH, 2 M

Sodium hydroxide, NaOH, 6 M

Sucrose

Filtration apparatus

Glass stirring rod

Large glass beaker

Magnetic stirrer/hot plate with stir bar

Silver Recovery

Silver may be recovered and recycled for future use by dissolving the metal or

metal compound in nitric acid, precipitating silver chloride and reducing the latter

to silver metal. Recovery of silver metal from AgCl may be achieved by reduction

with sucrose in basic solution or zinc metal in acid solution. The first step must be

done in a fume hood due to the possible production of NO2, a toxic brown gas. Note

that PbCl2 will co-precipitate with AgCl in the second step if the original silver is

contaminated with lead. The third step may be omitted, and the silver reclaimed in

the form of the precipitated silver chloride, if the original silver was relatively pure

(see Procedure A).

The chemical reactions are as follows. Oxidation of silver metal may occur by one

of two possible mechanisms:

2Ag(s) + 2HNO3 → 2AgNO3(aq) + H2(g)

Ag(s) + 2HNO3(aq) → AgNO3(aq) + NO2(g) + H2O

Ag+(aq) + Cl−(aq) → AgCl(s)

AgCl + NaOH(aq) + Sucrose → Ag(s)*

*Sucrose is hydrolyzed to the reducing sugars glucose and fructose in basic

solution. These sugars are oxidized to gluconic acids in the process of reducing Ag+

ions to silver metal. The silver metal will be obtained in the form of a brown powder.

Silver(I) compounds, such as AgCl, are photosensitive and must be stored in dark

bottles to prevent light-catalyzed reduction to silver.

Silver or silver ions may also be precipitated in the form of silver chloride to

reduce the volume of hazardous waste requiring disposal (see Procedure B).

Ag+(aq) + Cl−(aq) → AgCl(s)

Procedure A: Silver Recovery Process

or

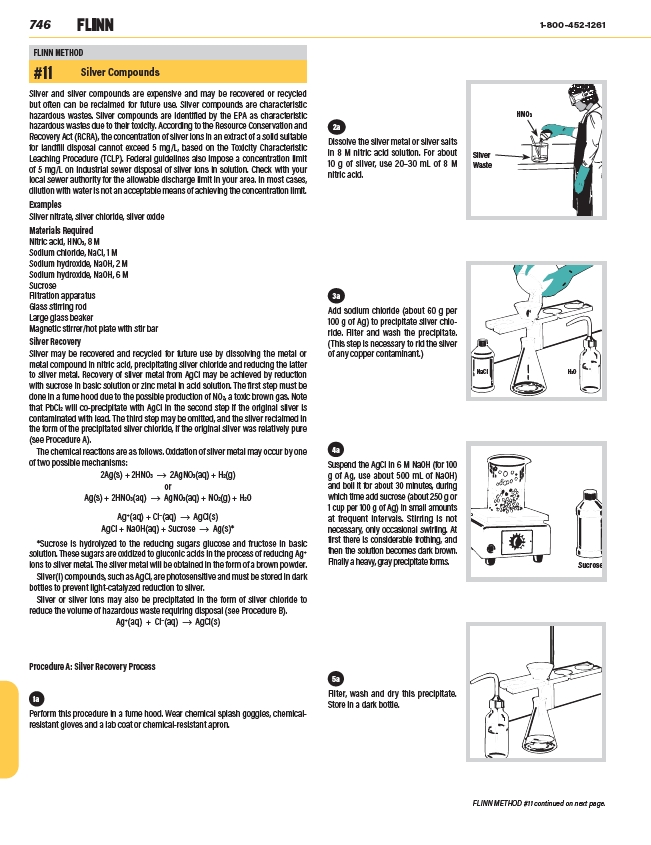

1a

Perform this procedure in a fume hood. Wear chemical splash goggles, chemicalresistant

gloves and a lab coat or chemical-resistant apron.

FLINN METHOD #11 continued on next page.

2a

Dissolve the silver metal or silver salts

in 8 M nitric acid solution. For about

10 g of silver, use 20–30 mL of 8 M

nitric acid.

HNO3

Silver

Waste

3a

Add sodium chloride (about 60 g per

100 g of Ag) to precipitate silver chloride.

Filter and wash the precipitate.

(This step is necessary to rid the silver

of any copper contaminant.)

NaCl H2O

4a

Suspend the AgCl in 6 M NaOH (for 100

g of Ag, use about 500 mL of NaOH)

and boil it for about 30 minutes, during

which time add sucrose (about 250 g or

1 cup per 100 g of Ag) in small amounts

at frequent

intervals. Stirring is not

necessary, only occasional swirling. At

first there is considerable frothing, and

then the solution becomes dark brown.

Finally a heavy, gray precipitate forms. Sucrose

5a

Filter, wash and dry this precipitate.

Store in a dark bottle.